Grade 2 Titanium Fasteners Specification

- ASME SF 468

- ASTM F468

The Titanium Grade 2 Fasteners offer optimum ductility and cold formability. Also, these fasteners have high demand because of their quality, durability, and corrosion resistance. These fasteners have aluminum, vanadium, nickel, ruthenium, molybdenum, chromium, zirconium, and much more. These fasteners have many excellent characteristics, such as heat resistance, conductivity, microstructure, creep, corrosion resistance, and many more. These Cp Grade 2 Titanium Anchor Bolt

have various usages in many sectors because of their excellent quality, availability at an affordable price, low maintenance cost, and everlasting usage. These fasteners are the best-suited product to provide excellent industrial and commercial application solutions. These Fasteners are available all over the industries in different sizes, shapes, thicknesses, and dimensions.

Table of Content

Dalloyed Works is a well-known and appreciated manufacturer, exporter, and supplier of these Titanium Grade 2 Fasteners in the market in huge quantities. We are manufacturing these Fasteners with several benefits and features that will help fulfill the needs of our clients and industries. When the final products are ready for delivery, then before the final delivery, we perform numerous destructive and non-destructive tests of ASTM F468 UNS R50400 Threaded Rods by using the latest tools and techniques.

Titanium Grade 2 Fasteners Specification

Grade 2 Titanium Fasteners Specification

Titanium Grade 2 Hot Forging Fasteners Length

ASME SF 468 Gr 2 Fasteners Sizes

Cp Grade 2 Titanium Studs Standard

ASTM F468 Stud Bolt Threads

ASTM F468 UNS R50400 Threaded Rod Applications

Titanium Cp Grade 2 Hex Bolts Head Drive

Ti Gr 2 Heavy Hex Bolt Certification

Titanium Gr 2 hex Nuts Form

Werkstoff Nr. 3.7035 Heavy Hex Nuts Value Added Services

ASME SF 468 titanium CP Grade 2 Socket Head Cap Screw Inspection Methods

UNS R50400 Surface Coating

Alloy Gr 2 Square Nuts Packaging

Ti Alloy Grade 2 Socket Cap Screws Origin

Cp Ti Grade 2 Lock Nut Benefits

ASME SF 468 Hex Cap Screws Process of Production

Various Types of Cp Grade 2 Titanium Fasteners

Grade 2 Titanium Alloy Eye Bolts

Grade 2 Titanium Lock Nuts

3.7035 Threaded Fastener

Ti Alloy Gr 2 Flange Lock Nut

Werkstoff Nr. 3.7035 Heavy Hex Nuts

DIN 3.7035 Hex Bolts

Titanium Gr 2 Machine Screws

W. Nr. 3.7035 Metric Threaded Rod

Titanium CP Grade 2 Self Drilling Screws

W. NR. 3.7035 Socket Cap Screws

Ti Gr 2 Square Bolts

Titanium CP grade 2 Threaded Rod

Sizes of Ti Grade 2 Heavy Duty Fastener

| INCH SIZE | METRIC SIZE | DECIMAL (INCH) | MILLIMETER (mm) |

| M6 | .2362 | 6.0000 | |

| 1/4 | .2500 | 6.3500 | |

| 5/16 | .3125 | 7.9375 | |

| M8 | .3149 | 8.0000 | |

| 3/8 | .3750 | 9.5250 | |

| M10 | .3937 | 10.0000 | |

| 7/16 | .4375 | 11.1125 | |

| M12 | .4724 | 12.0000 | |

| 1/2 | .5000 | 12.7000 | |

| 9/16 | .5625 | 14.2875 | |

| 5/8 | .6250 | 15.8750 | |

| M16 | .6299 | 16.0000 | |

| 3/4 | .7500 | 19.0500 | |

| M20 | .7874 | 20.0000 | |

| 7/8 | .8750 | 22.2250 | |

| M24 | .9448 | 24.0000 | |

| 1 | 1.0000 | 25.4000 | |

| 1 1/8 | 1.1250 | 28.5750 | |

| M30 | 1.1811 | 30.0000 | |

| 1 1/4 | 1.2500 | 31.7500 | |

| M36 | 1.4173 | 32.0000 | |

| 1 1/2 | 1.5000 | 38.1000 | |

| M42 | 1.6535 | 42.0000 | |

| 1 3/4 | 1.7500 | 44.4500 | |

| M48 | 1.8898 | 48.0000 | |

| 2 | 2.0000 | 50.8000 | |

| M56 | 2.2047 | 56.0000 | |

| 2 1/2 | 2.5000 | 63.5000 | |

| 3 | 3.0000 | 76.2000 |

Weight chart of Werkstoff Nr. 3.7035 Nut

| Size | Square | Heavy Hex | Finished Jam | Finished Hex | Heavy Square | Heavy Hex Jam |

| 1/2″ | 5.78 | 6.54 | 2.62 | 3.75 | 7.87 | 4.00 |

| 5/8″ | 10.8 | 11.9 | 4.93 | 7.33 | 14.3 | 6.96 |

| 3/4″ | 15.4 | 19.3 | 7.70 | 11.9 | 23.5 | 11.0 |

| 7/8″ | 24.5 | 29.7 | 12.0 | 19.0 | 36.2 | 16.7 |

| 1″ | 36.3 | 42.5 | 17.6 | 28.3 | 51.5 | 23.5 |

| 11/8″ | 52.5 | 59.2 | 24.7 | 40.3 | 72.4 | 32.4 |

| 11/4″ | 70.6 | 78.6 | 36.1 | 54.3 | 95.5 | 45.8 |

| 13/8″ | 94.5 | 102 | 47.9 | 73.0 | 125.0 | 59.3 |

| 11/2″ | 122 | 131 | 60.9 | 94.3 | 161 | 74.8 |

| 15/8″ | 162 | 91.6 | ||||

| 13/4″ | 204 | 100 | 151 | 114 | ||

| 17/8″ | 241 | 134 | ||||

| 2″ | 299 | 140 | 224 | 165 | ||

| 21/4″ | 419 | 227 | ||||

| 21/2″ | 564 | 332 | ||||

| 23/4″ | 738 | 429 | ||||

| 3″ | 950 | 545 | ||||

| 31/4″ | 1194 | 651 | ||||

| 31/2″ | 1526 | 851 | ||||

| 33/4″ | 1812 | 1005 | ||||

| 4″ | 2180 | 1200 |

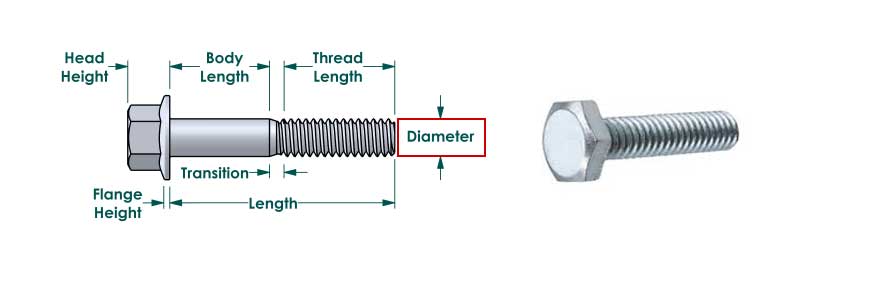

Dimension of Grade 2 Titanium Bolt

| BODY DIAMETER | HEAD THICKNESS ASTM A193 |

ACROSS ASTM A193 FLATS |

ACROSS ASTM A193 CORNERS |

|||||

|---|---|---|---|---|---|---|---|---|

| D (MAX) | D (MIN) | H (MAX) | H (MIN) | F (MAX) | F (MIN) | C (MAX) | C (MIN) | |

| m100 | 90.00 | 99.13 | 63.9 | 60.10 | 145.00 | 140.00 | 167.43 | 159.60 |

| m90 | 90.00 | 89.13 | 57.74 | 54.26 | 130.00 | 125.50 | 150.11 | 143.07 |

| m80 | 80.00 | 79.26 | 51.58 | 48.42 | 115.00 | 111.00 | 132.72 | 126.54 |

| m72 | 72.00 | 71.26 | 46.45 | 43.55 | 105.00 | 101.40 | 121.24 | 115.60 |

| m64 | 64.00 | 63.26 | 41.32 | 38.68 | 95.00 | 91.80 | 109.70 | 104.65 |

| m56 | 56.00 | 55.26 | 36.2 | 33.80 | 85.00 | 82.20 | 98.15 | 93.71 |

| m48 | 48.00 | 47.38 | 31.07 | 28.93 | 75.00 | 72.60 | 86.60 | 82.76 |

| m42 | 42.00 | 41.38 | 26.97 | 25.03 | 65.00 | 62.90 | 75.06 | 71.71 |

| m36 | 36.00 | 35.61 | 23.38 | 21.63 | 55.00 | 53.80 | 63.51 | 60.79 |

| m30 | 30.00 | 29.67 | 19.48 | 17.92 | 46.00 | 45.00 | 53.12 | 50.85 |

| m24 | 24.00 | 23.67 | 15.44 | 14.56 | 36.00 | 35.00 | 41.57 | 39.55 |

| m20 | 20.00 | 19.67 | 12.88 | 12.12 | 30.00 | 29.16 | 34.64 | 32.95 |

| m16 | 16.00 | 15.73 | 10.32 | 9.68 | 24.00 | 23.67 | 27.71 | 26.75 |

| m14 | 14.00 | 13.73 | 9.09 | 8.51 | 22.00 | 20.67 | 24.25 | 23.35 |

| m12 | 12.00 | 11.73 | 7.76 | 4.24 | 19.00 | 17.73 | 20.78 | 20.03 |

| m10 | 10.00 | 9.78 | 6.63 | 6.17 | 17.00 | 15.73 | 18.48 | 17.77 |

Chemical Compatibility and Incompatibility of W. NR. 3.7035 Machine Fastener

| Chemical Compatibility of Fastener | Chemical Incompatibility of Fastener |

|---|---|

| Acetic Acid - Good | Fluorine - Corrosive |

| Benzene - fair | Iodine - Corrosive |

| Ethanol- Good | Perchloric Acid - Severe corrosion |

| Water - Excellent | Nitric Acid (Conc.) - Severe corrosion |

| Hydrogen Peroxide - Good | Bromine -Corrosive |

Torque Chart of Cp Ti grade 2 Bolts/ Screw

| Titanium Grade 2 Bolt/Screw | |||

| Diameter (in) | Threads/in | (Dry) | (Lubricated) |

| 5/8" | 11 | 81.6 | 61.2 |

| 18 | 92.4 | 69.3 | |

| 9/16" | 12 | 59.1 | 44.3 |

| 18 | 65.9 | 49.5 | |

| 7/8" | 9 | 233 | 175 |

| 14 | 258 | 193 | |

| 1-1/4" | 7 | 609 | 457 |

| 12 | 674 | 505 | |

| 3/8" | 16 | 16.8 | 12.6 |

| 24 | 19.0 | 14.2 | |

| 5/16" | 18 | 9.5 | 7.1 |

| 24 | 10.5 | 7.9 | |

| 1/2" | 13 | 41.0 | 30.7 |

| 20 | 46.2 | 34.6 | |

| 7/16" | 14 | 26.8 | 20.2 |

| 20 | 30.0 | 22.5 | |

| 1" | 8 | 350 | 263 |

| 14 | 392 | 295 | |

Equivalent Grades of Titanium Grade 2 Fasteners

| STANDARD | WERKSTOFF NR.(Germany) | UNS(North America) |

| Titanium Gr.2 | 3.7035 | R50400 |

Chemical Composition of DIN 3.7035 Threaded Rod

Carbon

Hydrogen

Titanium

Iron

Nitrogen

Oxygen

Mechanical Properties of Ti Gr 2 Square Nut

Psi – 49900 , MPa – 344

Psi – 39900 , MPa – 275

20 %

4.5 g/cm³

1665 °C (3030 °F)

425 °C

Get in Touch

Call us on

Email us