Inconel 601 Steel Fasteners Specification

- ASME SB166

- ASTM B166

These Inconel 600 Fasteners contain nickel-based elements. These Fasteners are also having the addition of chromium. These Fasteners have excellent resistance to aqueous corrosion and high mechanical strength. These Fasteners are readily formed and machined. These Inconel Fasteners are a family of nickel-chromium-molybdenum alloys. It is used for its strength at elevated temperatures and good corrosive resistance. These Inconel 601 fasteners have high resistance. Also, these alloys are commonly used in high-temperature applications. These Fasteners are also used in highly corrosive environments. These Fasteners have outstanding resistance to oxidation and other forms of high-temperature corrosion. Inconel 625 has chromium and molybdenum that offers remarkable resistive properties. These Fasteners also have aluminium and titanium. These Fasteners are finely finished, precise pattern, corrosion free, and highly robust. These fasteners are offered in various length sizes and shapes and are available at affordable prices.

Table of Content

Dalloyed Works is a famous manufacturer and supplier of Inconel 600, 601, and 625 Fasteners. We, Dalloyed Works, manufacture Inconel 600 Fasteners with premium quantity and quality of raw materials procured from the trusted supplier by taking advice from our professional team. Dalloyed Works supplies customized and non-customized Inconel 601 fasteners with proper packaging materials and performs smooth, convenient, time and damages-free delivery to our estimated customer.

Inconel Forged Fasteners Specification

Inconel 601 Steel Fasteners Specification

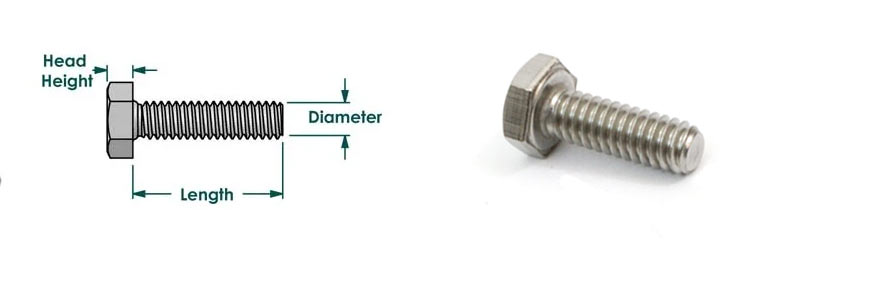

Alloy 625 Hex Bolts Length

Werkstoff NR. 2.4851 Hex Cap Screws Grades

EN 2.4816 Fixings and Fasteners Standard

ASME SB166 Plain Washer Threads

DIN 2.4856 Lock Nut Size

600 Inconel Threaded Stud Head Drive

NA 49 Self Tapping Screws Test Certificate

ASME SF468 Eye Bolts Form

Alloy 601 Self Tapping Screws Marking

UNS N06600 Fasteners Packaging

Inconel Alloy 601 Wood Screws Inspection Methods

WNR 2.4856 Socket Cap Screws Documentation

Inconel 625LCF Heavy Hex Bolt Origin

Chemical Compatibility of SB166 Square Bolts

Chemical UnCompatibility of WNR 2.4856 Industrial Fasteners

Types of Inconel Alloy Fasteners

2.4816 Bolts

ASTM B166 Countersunk Washer

Alloy UNS N06601 Flat Washer

Nickel Alloy 600 Hex Nut

Alloy 2.4856 Lock Nut

UNS N06625 Machine Screws

NICR23fe Nuts

ASTM B166 UNS N06601 Plain Washer

DIN 2.4856 Socket Cap Screws

F468 UNS N06625 Square Bolts

Nickel 601 Stud Bolts

JIS NCF 625 Wood Screws

Weight Chart of ASTM B166 UNS 6600 Fasteners

| APPROXIMATE WEIGHT IN KGS FOR 100 NOS | ||||||||||

| LENGTH | DIAMETER | |||||||||

| M 22 | M 20 | M 18 | M 16 | M 14 | M 12 | M 10 | M 8 | M 6 | M 5 | |

| 400 mm | 113.636 | 69.444 | 39.063 | |||||||

| 380 mm | 108.696 | 66.667 | 37.037 | |||||||

| 360 mm | 104.167 | 63.291 | 35.211 | |||||||

| 340 mm | 98.039 | 60.241 | 33.557 | |||||||

| 320 mm | 92.593 | 56.818 | 31.646 | |||||||

| 300 mm | 104.167 | 87.719 | 53.763 | 29.940 | 20.325 | |||||

| 280 mm | 98.039 | 81.967 | 50.505 | 28.090 | 19.157 | |||||

| 260 mm | 90.909 | 76.923 | 47.170 | 26.316 | 17.921 | |||||

| 250 mm | 87.719 | 74.627 | 45.455 | 25.381 | 17.301 | |||||

| 240 mm | 84.746 | 71.429 | 43.860 | 24.510 | 16.722 | |||||

| 220 mm | 79.365 | 65.789 | 40.650 | 22.624 | 15.528 | |||||

| 200 mm | 73.529 | 60.976 | 49.020 | 37.594 | 29.586 | 20.833 | 14.327 | |||

| 190 mm | 70.423 | 58.140 | 35.971 | 19.920 | 13.736 | |||||

| 180 mm | 67.568 | 55.556 | 34.247 | 26.882 | 19.011 | 13.123 | ||||

| 170 mm | 64.935 | 53.191 | 32.680 | 18.116 | 12.500 | |||||

| 160 mm | 61.728 | 50.505 | 40.984 | 31.056 | 24.272 | 17.241 | 11.905 | |||

| 150 mm | 58.824 | 48.544 | 37.594 | 29.412 | 22.222 | 16.340 | 11.312 | |||

| 140 mm | 55.556 | 46.296 | 35.461 | 27.933 | 20.833 | 15.432 | 10.707 | |||

| 130 mm | 52.632 | 43.478 | 34.722 | 26.316 | 20.000 | 14.535 | 10.101 | |||

| 120 mm | 50.000 | 40.984 | 32.895 | 24.631 | 18.797 | 13.624 | 9.506 | |||

| 110 mm | 47.170 | 38.168 | 31.250 | 23.041 | 17.730 | 12.723 | 8.881 | |||

| 100 mm | 46.296 | 35.714 | 27.778 | 21.459 | 16.340 | 11.820 | 8.251 | 4.873 | ||

| 90 mm | 41.667 | 33.113 | 26.042 | 19.841 | 14.925 | 10.917 | 7.634 | 4.472 | ||

| 80 mm | 40.000 | 30.303 | 24.510 | 18.248 | 13.889 | 10.000 | 7.013 | 4.072 | 2.111 | |

| 75 mm | 39.063 | 29.070 | 23.256 | 17.606 | 13.228 | 9.506 | 6.702 | 3.873 | 2.000 | |

| 70 mm | 35.461 | 27.778 | 22.124 | 16.835 | 12.987 | 9.058 | 6.394 | 3.671 | 1.890 | |

| 65 mm | 34.014 | 26.455 | 21.008 | 16.026 | 12.626 | 8.621 | 6.083 | 3.472 | 1.781 | |

| 60 mm | 32.051 | 25.126 | 20.000 | 15.244 | 12.255 | 8.183 | 5.774 | 3.270 | 1.670 | |

| 55 mm | 30.120 | 23.810 | 18.868 | 14.409 | 11.628 | 7.740 | 5.464 | 3.071 | 1.560 | |

| 50 mm | 28.409 | 22.727 | 17.857 | 13.624 | 11.261 | 7.299 | 5.155 | 2.870 | 1.450 | 1.030 |

| 45 mm | 21.739 | 17.241 | 12.821 | 10.504 | 6.859 | 4.840 | 2.671 | 1.340 | 0.958 | |

| 40 mm | 20.747 | 16.667 | 12.107 | 10.288 | 6.410 | 4.533 | 2.470 | 1.230 | 0.881 | |

| 35 mm | 19.608 | 16.026 | 11.416 | 10.000 | 5.974 | 4.223 | 2.271 | 1.120 | 0.804 | |

| 30 mm | 18.657 | 10.707 | 9.690 | 5.574 | 3.912 | 2.070 | 1.010 | 0.737 | ||

| 25 mm | 8.170 | 5.252 | 3.660 | 1.871 | 0.897 | 0.660 | ||||

| 20 mm | 4.892 | 3.411 | 1.711 | 0.812 | 0.598 | |||||

| 16 mm | 3.211 | 1.590 | 0.743 | 0.448 | ||||||

HS Code of WNR 2.4816 Heavy Duty Fasteners

| Product Description | HS Code |

|---|---|

| Inconel 625 Fasteners | 7318 |

Sizes of 601 Nickel Alloy Cold Forged Fasteners

| INCONEL 601 FASTENERS SIZES | ||

| Sizes | 3/8″-16 x 1-1/4″ | 3/8″-16 x 1″ Grade 18-8 |

| 1/2″-13 x 2″ | 1/4″-20 x 1″ Grade 18-8 | |

| 1/4″-20 x 1″ | 3/8″-16 x 1-1/4″ | |

| 1/4″-20 x 3/4″ Grade 18-8 | 5/8″-11 x 2″ | |

| 1/2″-13 x 2″ | 3/8″-16 x 1-1/2″ | |

| 3/8″-16 x 1-1/2″ | 3/8″-16 x 2″ | |

| 1/2″-13 x 1-1/2″ | 3/8″-16 x 1″ | |

| 1/2″-13 x 1-1/2″ | 5/8″-11 x 2-1/2″ | |

| 5/8″-11 x 2″ | 5/16″-18 x 1″ | |

| 3/8″-16 x 1″ | 1/4″-20 x 3/4″ | |

Torque Chart of Inconel Alloy 601 Eye Bolts

| Inconel 601 Bolt/Screw | |||

|---|---|---|---|

| Nominal Diameter (in) | Torque ft-lb | Threads/in | Torque ft-lb |

| (Dry) | (Lubricated) | ||

| 1-1/4" | 451 | 7 | 338 |

| 499 | 12 | 374 | |

| 1/4" | 3.4 | 20 | 2.5 |

| 3.9 | 28 | 2.9 | |

| 1" | 259 | 8 | 194 |

| 290 | 14 | 218 | |

| 1-1/2" | 784 | 6 | 588 |

| 882 | 12 | 662 | |

| 1/2" | 30.3 | 13 | 22.7 |

| 34.2 | 20 | 25.6 | |

| 3/4" | 107 | 10 | 80 |

| 119 | 16 | 90 | |

| 3/8" | 12.4 | 16 | 9.3 |

| 14.1 | 24 | 10.5 | |

| 5/8" | 60.4 | 11 | 45.3 |

| 68.4 | 18 | 51.3 | |

| 5/16" | 7.0 | 18 | 5.3 |

| 7.8 | 24 | 5.8 | |

| 7/8" | 173 | 9 | 130 |

| 191 | 14 | 143 | |

| 7/16" | 19.9 | 14 | 14.9 |

| 22.2 | 20 | 16.7 | |

| 9/16" | 43.7 | 12 | 32.8 |

| 48.8 | 18 | 36.6 | |

Dimension of Inconel® Alloy 625 Nylock Nuts

| Size | Nominal (Major) Diameter [in] |

Width Across Flats | Thickness | ||

| Nominal [in] | Minimum [in] | Minimum [in] | Maximum [in] | ||

| 3/8" | 0.375 | 5/8"(0.625) | 0.607 | 0.239 | 0.257 |

| 5/16" | 0.312 | 9/16"(0.562) | 0.545 | 0.208 | 0.225 |

| 1/4" | 0.250 | 7/16"(0.438) | 0.423 | 0.178 | 0.193 |

| #10 | 0.190 | 3/8"(0.375) | 0.362 | 0.117 | 0.130 |

| #8 | 0.164 | 11/32"(0.344) | 0.332 | 0.117 | 0.130 |

| #6 | 0.138 | 5/16"(0.312) | 0.302 | 0.102 | 0.114 |

| #4 | 0.112 | 1/4"(0.250) | 0.241 | 0.087 | 0.098 |

| #2 | 0.086 | 3/16"(0.188) | 0.180 | 0.057 | 0.066 |

| #0 | 0.060 | 5/32"(0.156) | 0.150 | 0.043 | 0.050 |

Price List of 2.4816 Inconel Fasteners

| Fasteners | Size | Price in US $ |

| HEX BOLT | 1/2 - 13UNC X 60MM | US $ 4.80 |

NUT |

M 22 X |

US $ 15.56 |

STUD BOLT |

M8 X 225MM |

US $ 2.83 |

NUT |

M 16 |

US $ 6.65 |

SCREWS |

M 16X90 MMl |

US $ 14.26 |

STUD BOLT |

M18 X 75 MM |

US $ 40.84 |

FLAT WASHER |

M16 |

US $ 9.21 |

Washer |

M20 |

US $ 9.39 |

SCREW |

230MM |

US $ 10.44 |

SCREW |

150MM |

US $ 8.53 |

Chemical Composition of Alloy 600 Construction Fasteners

Carbon

Manganese

Silicon

Sulphur

Copper

Iron

Nickel

Chromium

Nickel 601 Fasteners

Carbon

Manganese

Silicon

Sulphur

Copper

Iron

Nickel

Chromium

Inconel 625 Fasteners

Carbon

Manganese

Silicon

Sulphur

Iron

Nickel

Chromium

Mechanical Properties of Nickel 600 Marine Fasteners

600 :8.47 g/cm3

601 : 8.1 g/cm3

625 : 8.4 g/cm3

1413 °C (2580 °F)

1411 °C (2571 °F)

1350 °C (2460 °F)

MPa – 655

MPa – 550

MPa – 930

Psi – 45,000

Psi – 30,000

Psi – 75,000

2000°F (1095°C)

up to 2200°F (1204°C)

2000 F - 1093 C

MPa – 655

MPa – 550

MPa – 930

Equivalent Grades of Inconel Heavy Duty Fasteners

| STANDARD | WERKSTOFF NR.(Germany) | UNS(North America) | JIS (Japan) | BS (British Standard) | GOST (Russia) | AFNOR (France) | EN (Europe) |

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

| Inconel 601 | 2.4851 | N06601 | NCF 601 | NA 49 | XH60BT | NC23FeA | NiCr23Fe |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | N600DNB4M | NiCr22Mo9Nb |

Surface Treatments of Alloy UNS N06626 Fasteners

Electrical Properties of 2.4816 Inconel 600 Deck Fasteners

| Electrical Properties | |||

| Curie Temperature | Max -196 °C | Max -321 °F | |

| Electrical Resistivity | 0.000119 Ohm-Cm | 0.000119 Ohm-Cm | |

| Magnetic Permeability | 1.003 | 1.003 | At 200 Oersted (15.9 KA/M) |

Inconel Fasteners are used in a wide range of Applications and Industries. Below are a few of them:

Get in Touch

Call us on

Email us