Alloy K500 Tapper Washer Specification

- ASME SF467

- ASTM F467

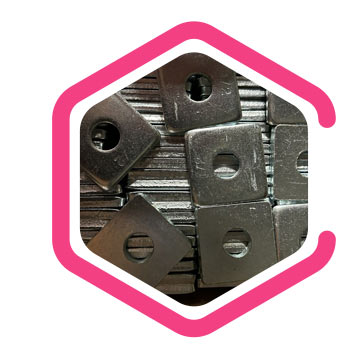

The Monel K500 Washers are made of a material such as Nickel and Copper with Trace Amounts of Iron, Manganese, Carbon, and Silicon which provide excellent corrosion resistance with the additional feature of increased tensile strength and hardness. Monel K-500 Washers could have a greater tendency toward stress-related corrosion cracking in some environments and continually maintain higher power. These Monel Alloy K-500 Washers are offered in various shapes and sizes. These Washers are also widely known for their beneficial features and qualities. They provide key functionality such as longer working life, corrosion resistance, and many more. These Washers are available in all dimensions and specifications to deliver suitable Washers for specific industrial needs. Alloy K-500 Washers can be commonly used for various applications such as bracing, structural supports, brackets, architectural trim, and other parts requiring grinding, machining, welding, and polishing. ASTM F467 UNS N05500 Square Washer undergo destructive and non-destructive tests.

Table of Content

Dalloyed Works is one of the leading manufacturers and suppliers of Washers. We manufacture these Washers in many materials and grades to deliver suitable solutions to our esteemed clients. We produce our Nickel Alloy K500 using pure Monel K-500 and utilizing new machines and technology in our manufacturing unit. We aim to provide excellent quality Monel Alloy K-500 to our customers. We ensure all qualities of Washers and then pack them in suitable materials to ensure damage-free delivery.

ASTM F467 Plain Washer Specification

Alloy K500 Tapper Washer Specification

Monel Alloy K500 Spring Washers Length

Monel K500 Washers Sizes

UNS N05500 Lock Washers Standard

2.4375 Star Washers Threads

K500 Monel Beveled Washer Documentation

Monel® Alloy K500 Tooth Washer Head Drive

ASTM F467 UNS N05500 Square Washer

Alloy K-500 Split Washer Packaging

K500 Monel Alloy Flat Washer Origin

ASTM F467 Countersunk Washer Benefits

WERKSTOFF NR.2.4375 Plain Washer External Coating

Different Types of Monel K500 Washers

Alloy K500 Falt Washer

ASTM F467 UNS N05500 Countersunk Washer

ASME SF467 Ogee Washer

K500 Monel Plain washer

Nickel Alloy K500 Round Plate Washer

Werkstoff NR. 2.4375 Split Washer

Monel Alloy K500 Square Washers

DIN 2.4375 Star Washers

WNR 2.4375 Beveled Washers

Dimension Chart of Monel 2.4375 Flat Washer

| Size | Inside Diameter | Outside Diameter | Thickness |

|---|---|---|---|

| #2 | 3/32" | 1/4" | .020" |

| 1-1/2 | 1-7/16" | 3" | 3/16" |

| 1/4 | 9/32" | 5/8" | 1/16" |

| #4 | 1/8" | 5/16" | 1/32" |

| 3/4 | 13/16" | 1-1/2" | 9/64" |

| #8 | 3/16" | 7/16" | 3/64" |

| 1-3/4 | 1-7/8" | 4" | 3/16" |

| #10 | 7/32" | 1/2" | 3/64" |

| 2 | 2-1/8" | 4-1/2" | 3/16" |

| 1-1/4 | 1-5/16" | 2-1/2" | 5/32" |

| #6 | 5/32" | 3/8" | 3/64" |

| 7/8 | 15/16" | 1-3/4" | 9/64" |

| 3/8 | 13/32" | 13/16" | 1/16" |

| 1-1/8 | 1-3/16" | 2-1/4" | 9/64" |

| 7/16 | 15/32" | 59/64" | 1/16" |

| 1-5/8 | 1-3/4" | 3-3/4" | 3/16" |

| 1/2 | 17/32" | 1-1/16" | 3/32" |

| 9/16 | 19/32" | 1-3/16" | 3/32" |

| 5/16 | 11/32" | 11/16" | 1/16" |

| 5/8 | 21/32" | 1-5/16" | 3/32" |

| 1" | 1-1/16" | 2" | 9/64" |

| Size | USS | SAE | ||||

| Inside Diameter (A) |

Outside Diameter (B) |

Thickness (C) |

Inside Diameter (A) |

Outside Diameter (B) |

Thickness (C) |

|

| #12 | - | - | - | 1/4" | 9/16" | 0.065" |

| #10 | - | - | - | 7/32" | 1/2" | 0.049" |

| #8 | - | - | - | 3/16" | 7/16" | 0.049" |

| #6 | - | - | - | 5/32" | 3/8" | 0.049" |

| #4 | - | - | - | 1/8" | 5/16" | 0.032" |

| #2 | - | - | - | 3/32" | 1/4" | 0.020" |

| 2" | 2-1/8" | 4-1/2" | 0.213" | - | - | - |

| 1" | 1-1/16" | 2-1/2" | 0.165" | 1-1/16" | 2" | 0.134" |

| 1-1/8" | 1-1/4" | 2-3/4" | 0.165" | - | - | - |

| 1-5/8" | 1-3/4" | 3-3/4" | 0.180" | - | - | - |

| 1/4" | 5/16" | 0.734" | 0.065" | 9/32" | 5/8" | 0.065" |

| 1-3/8" | 1-1/2" | 3-1/4" | 0.180" | - | - | - |

| 1-3/4" | 1-7/8" | 4" | 0.180" | - | - | - |

| 1-1/2" | 1-5/8" | 3-1/2" | 0.180" | - | - | - |

| 1/2" | 9/16" | 1-3/8" | 0.109" | 17/32" | 1-1/16" | 0.095" |

| 1-1/4" | 1-3/8" | 3" | 0.165" | - | - | - |

| 9/16" | 5/8" | 1-15/32" | 0.109" | 19/32" | 1-5/32" | 0.095" |

| 7/16" | 1/2" | 1-1/4" | 0.083" | 15/32" | 15/16" | 0.065" |

| 5/16" | 3/8" | 7/8" | 0.083" | 11/32" | 11/16" | 0.065" |

| 7/8" | 15/16" | 2-1/4" | 0.165" | 15/16" | 1-3/4" | 0.134" |

| 5/8" | 11/16" | 1-3/4" | 0.134" | 21/32" | 1-5/16" | 0.095" |

| 3/8" | 7/16" | 1" | 0.083" | 13/32" | 13/16" | 0.065" |

| 3/4" | 13/16" | 2" | 0.148" | 13/16" | 1-15/32" | 0.134" |

Weight Chart of ASME SF467 N05500 Dock Washers

| APPROX. WEIGHT IN KGS FOR 100 NOS | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SIZE | PLAIN PUNCHED WASHER IS:K5006 |

HEAVY WASHER IS:6610 |

MACHINED WASHER IS:K5006 |

SQUARE | TAPPER | WASHERS | SPRING WASHER FLAT SECTION IS:3063-72 | SPRING WASHER SQUARE SECTION IS:6735-72 DIN : 7980 |

Size (Inches) | PLAIN WASHER BS:3410 TABLE 7 |

|||

| MACHINED | HIGH STRENGTH FRICTION GRIP |

||||||||||

| FOR CHANNELS IS:5372-75 |

FOR I-BEAM IS:5374-75 |

TYPE-B (CHANNELS) IS : 6649-85 |

TYPE-C ( I-BEAMS ) IS : 6649-85 |

||||||||

| M-12 | 0.58 | 1.90 | 0.62 | 2.00 | 2.20 | 2.00 | 1.80 | 0.38 | 0.23 | 1/2" | 1.07 |

| M-22 | 1.75 | 7.50 | 7.00 | 1.65 | 1.36 | 7/8" | 4.27 | ||||

| M-42 | 17.50 | 20.10 | 18.30 | 11.10 | 8.00 | ||||||

| M-52 | 31.90 | 33.00 | 18.20 | ||||||||

| M-72 | 63.40 | 24.00 | |||||||||

| M-3 | 0.01 | 0.01 | |||||||||

| M-33 | 7.10 | 12.00 | 7.54 | 21.00 | 23.50 | 23.00 | 22.50 | 6.30 | 3.50 | ||

| M-4 | 0.02 | 0.02 | |||||||||

| M-14 | 0.82 | 0.60 | 0.38 | ||||||||

| M-24 | 3.11 | 6.30 | 3.30 | 13.50 | 16.00 | 6.50 | 6.00 | 2.62 | 1.81 | 1" | 6.13 |

| M-64 | 55.40 | 21.80 | |||||||||

| M-5 | 0.04 | 0.04 | 0.03 | 0.03 | |||||||

| M-45 | 21.20 | 22.20 | 22.00 | 11.70 | 8.53 | ||||||

| M-6 | 0.11 | 0.11 | 0.08 | 0.04 | 1/4" | 0.21 | |||||

| M-16 | 1.06 | 2.90 | 1.13 | 3.40 | 3.75 | 9.00 | 8.50 | 0.89 | 0.59 | 5/8" | 1.85 |

| M-30 | 5.05 | 10.10 | 5.36 | 16.50 | 18.70 | 17.50 | 16.00 | 4.43 | 3.20 | 1.1/4" | 9.90 |

| M-36 | 8.73 | 14.60 | 9.20 | 25.50 | 29.20 | 26.50 | 26.00 | 6.73 | 5.25 | 1.1/2" | 17.24 |

| M-56 | 47.90 | 19.30 | |||||||||

| M-27 | 3.94 | 8.00 | 4.23 | 12.50 | 15.00 | 12.00 | 11.50 | 2.87 | 2.06 | 1.1/8" | 7.69 |

| M-8 | 0.20 | 0.21 | 1.10 | 1.20 | 0.16 | 0.11 | 5/16" | 0.35 | |||

| M-18 | 1.27 | 0.97 | 0.66 | ||||||||

| M-68 | 57.40 | ||||||||||

| M-48 | 28.40 | 26.00 | 29.40 | 12.30 | 9.00 | 2" | 27.78 | ||||

| M-39 | 12.60 | 16.70 | 13.30 | 28.30 | 34.50 | 7.17 | 5.61 | ||||

| M-10 | 0.39 | 1.60 | 0.40 | 1.00 | 1.10 | 0.25 | 0.20 | 3/8" | 0.48 | ||

| M-20 | 1.64 | 4.40 | 1.72 | 5.80 | 6.70 | 8.50 | 8.00 | 1.52 | 1.23 | 3/4" | 2.91 |

| M-60 | 51.60 | 20.30 | |||||||||

Applications of Nickel Alloy K500 Star Washers

| Grade | HS Code |

|---|---|

| Washer | 75051220 |

Equivalent Grades of Monel Alloy K500 Split Washers

| STANDARD | WERKSTOFF NR.(Germany) | UNS(North America) | JIS (Japan) | BS (British Standard) | GOST (Russia) | AFNOR (France) | EN (Europe) |

| Monel K500 | 2.4375 | N05500 | - | - | - | - | - |

Chemical Composition of DIN 2.4375 Ogee Washers

Carbon

Manganese

Silicon

Sulphur

Iron

Copper

Nickel

Mechanical Properties of K500 Monel Round Plate Washer

Psi – 160000 , MPa – 1100

Psi-115000 , MPa – 790

20 %

8.44 g/cm³

1350 °C (2460 °F)

up to 480 °C

Get in Touch

Call us on

Email us