Monel 2.4360 Wing Nuts Specification

- ASTM F467

- ASME SF467

Monel is an alloy consisting of monel, copper, and iron, which provide high corrosion resistance. It also offers excellent resistance to the acidic environment, which is the most demanding product for this feature. Also, these Monel 400 Nuts have elevated workability, formability, machinability, fabricability, weldability, etc. Due to the fabricability property, these are easily modified into a sophisticated design. These can be used in industries such as Chemicals, Power Generation, Pharmaceuticals, sugar mills, and engineering sectors. Also, these Nuts are fabricated using superior-quality raw materials procured from reliable vendors. Monel Alloy 400 Nuts are most amazingly known for their superb finish. Excellent quality ASTM F467 UNS N04400 Eye Nuts are provided in different outer diameters, types, wall thicknesses, shapes, and dimensions. These nuts are manufactured using both traditional and modern technology. This manufacturing process makes DIN 2.4360 Flange Nuts have all beneficial features.

Table of Content

Dalloyed Works is a renowned manufacturer, stockist, and exporter of ASME SF 467 N04400 Coupling Nuts . Our packaging material is of supreme quality, and our packaging practices ensure there is no damage to products during transportation. We are offering Alloy 400 Nuts at the best possible price. Dalloyed Works have consistently tried to innovate and deliver Monel 400 Nuts that meet all market demands.

Monel Alloy 400 Hex Nut Specification

Monel 2.4360 Wing Nuts Specification

Alloy 400 Square Nuts

Length

400 Nickel Panel Nuts Sizes

UNS 4400 Lock Nuts Standard

400 Alloy Hex Nut Threads

2.4360 Heavy Hex Nut External Coating

EN 2.4360 Flange Lock Nut Head Drive

WNR 2.4360 Eye Nut Form

ASME SF467 Coupling Nut Packaging

ASME SF 467 Wing Nuts Origin

400 Nickel Alloy Hex Head Nut Benefits

ASME SF 467 UNS 4400 Square Nut Production Process

Different Types of Monel 400 Nuts

Nickel Alloy 400 Coupling Nut

2.4375 Eye Nut

Monel Alloy 400 Flange Lock Nut

Alloy 400 Heavy Hex Nut

Nickel 400 Hex Nut

JIS NW 4400 Lock Nuts

Monel® Alloy 400 Panel Nuts

UNS N04400 Square Nuts

WERKSTOFF NR. 2.4360 Wing Nuts

Weight Chart Of Monel UNS N04400 Weld Nuts

| Size | Heavy Hex | Heavy Hex Jam | Finished Hex | Square | Heavy Square | Finished Jam |

| 33/4″ | 1812 | 1005 | ||||

| 31/4″ | 1194 | 651 | ||||

| 31/2″ | 1526 | 851 | ||||

| 23/4″ | 738 | 429 | ||||

| 21/4″ | 419 | 227 | ||||

| 21/2″ | 564 | 332 | ||||

| 17/8″ | 241 | 134 | ||||

| 15/8″ | 162 | 91.6 | ||||

| 13/8″ | 102 | 59.3 | 73.0 | 94.5 | 125.0 | 47.9 |

| 13/4″ | 204 | 114 | 151 | 100 | ||

| 11/8″ | 59.2 | 32.4 | 40.3 | 52.5 | 72.4 | 24.7 |

| 11/4″ | 78.6 | 45.8 | 54.3 | 70.6 | 95.5 | 36.1 |

| 11/2″ | 131 | 74.8 | 94.3 | 122 | 161 | 60.9 |

| 7/8″ | 29.7 | 16.7 | 19.0 | 24.5 | 36.2 | 12.0 |

| 5/8″ | 11.9 | 6.96 | 7.33 | 10.8 | 14.3 | 4.93 |

| 4″ | 2180 | 1200 | ||||

| 3″ | 950 | 545 | ||||

| 3/4″ | 19.3 | 11.0 | 11.9 | 15.4 | 23.5 | 7.70 |

| 2″ | 299 | 165 | 224 | 140 | ||

| 1″ | 42.5 | 23.5 | 28.3 | 36.3 | 51.5 | 17.6 |

| 1/2″ | 6.54 | 4.00 | 3.75 | 5.78 | 7.87 | 2.62 |

Size Chart Of Nickel Alloy 400 Dome Nuts

| Size Of Nut (millimeter) |

Diameter Of (millimeter) |

Height Table (millimeter) |

||

|---|---|---|---|---|

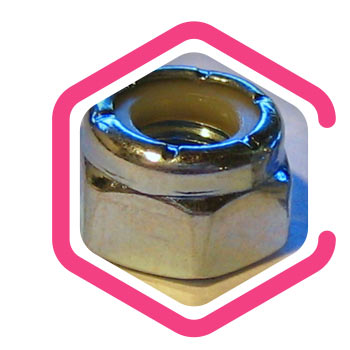

| Hex Nut | Jam Nut | Nylock Nut | ||

| 20 | 30 | 16 | 10 | 20 |

| 2 | 4 | 1.6 | 1.2 | - |

| 18 | 27 | 15 | 9 | 18.5 |

| 2.5 | 5 | 2 | 1.6 | - |

| 16 | 24 | 13 | 8 | 16 |

| 3 | 5.5 | 2.4 | 1.8 | 4 |

| 14 | 22 | 11 | 7 | 14 |

| 4 | 7 | 3.2 | 2.2 | 5 |

| 12 | 19 | 10 | 6 | 12 |

| 5 | 8 | 4 | 2.7 | 5 |

| 10 | 17 | 8 | 5 | 10 |

| 8 | 13 | 6.5 | 4 | 8 |

| 7 | 11 | 5.5 | 3.5 | - |

| 6 | 10 | 5 | 3.2 | 6 |

Dimension Chart of 400 Monel Coupling Nut

| Nominal Size Of Thread Diameter | F | G | H | ||||||

| Across Flats Width |

Across Corners Width |

Thickness Row | |||||||

| Basic | Maximum | Minimum | Maximum | Minimum | Basic | Maximum | Minimum | ||

| 1 | 1.0000 | 1-1/2 | 1.500 | 1.450 | 1.732 | 1.653 | 55/64 | .887 | .831 |

| 1/2 | .5000 | 3/4 | .750 | .736 | .866 | .840 | 7/16 | .448 | .427 |

| 1-1/2 | 1.500 | 2-1/4 | 2.250 | 2.175 | 2.598 | 2.480 | 1-9/32 | 1.ASTM A194 GR. 8 | 1.245 |

| 1/4 | .2500 | 7/16 | .438 | .428 | .505 | .488 | 7/32 | .226 | .212 |

| 1-1/8 | 1.1250 | 1-11/16 | 1.688 | 1.631 | 1.949 | 1.859 | 31/32 | .999 | .939 |

| 1-3/4 | 1.7500 | 2-5/8 | 2.625 | 2.538 | 3.031 | 2.893 | 1-1/2 | 1.540 | 1.460 |

| 1-3/8 | 1.3750 | 2-1/16 | 2.062 | 1.994 | 2.382 | 2.273 | 1-11/64 | 1.206 | 1.138 |

| 1-5/8 | 1.6250 | 2-7/16 | 2.438 | 2.356 | 2.815 | 2.686 | 1-25/64 | 1.429 | 1.353 |

| 2 | 2.0000 | 3 | 3.000 | 2.900 | 3.464 | 3.306 | 1-23/32 | 1.763 | 1.675 |

| 2-1/2 | 2.5000 | 3-3/4 | 3.750 | 3.625 | 4.330 | 4.133 | 2-5/32 | 2.209 | 2.105 |

| 2-1/4 | 2.2500 | 3-3/8 | 3.375 | 3.263 | 3.897 | 3.719 | 1-15/16 | 1.986 | 1.890 |

| 2-3/4 | 2.7500 | 4-1/8 | 4.125 | 3.988 | 4.763 | 4.546 | 2-3/8 | 2.431 | 2.319 |

| 3/4 | .7500 | 1-1/8 | 1.125 | 1.088 | 1.299 | 1.240 | 41/64 | .665 | .617 |

| 3/8 | .3750 | 9/16 | .562 | .551 | .650 | .628 | 21/64 | .337 | .479 |

| 5/16 | .3125 | 1/2 | .500 | .489 | .577 | .557 | 17/64 | .273 | .258 |

| 7/16 | .4375 | 11/16 | .688 | .675 | .794 | .768 | 3/8 | .385 | .365 |

| 9/16 | .5625 | 7/8 | .875 | .861 | 1.010 | .982 | 31/64 | .496 | .473 |

| 7/8 | .8750 | 1-5/16 | 1.312 | 1.269 | 1.516 | 1.447 | 3/4 | .776 | .724 |

| 5/8 | .6250 | 15/16 | .938 | .922 | 1.083 | 1.051 | 35/64 | .559 | .535 |

Thermal Properties of DIN 2.4360 Nylock Nuts

| Monel 400 Bolts And Nuts Thermal Properties | |||

| CTE, linear 20°C | 13.9 µm/m-°C | 7.72 µin/in-°F | 20-100°C |

| Heat Capacity | 0.427 J/g-°C | 0.102 BTU/lb-°F | |

| Thermal Conductivity | 21.8 W/m-K | 151 BTU-in/hr-ft²-°F | |

| Melting Point | 1300 – 1350 °C | 2370 – 2460 °F | |

| Solidus | 1300 °C | 2370 °F | |

| Liquidus | 1350 °C | 2460 °F | |

Physical Properties of Monel® 400 Eye Nut

| Properties | Metric | Imperial |

|---|---|---|

| Poisson’s ratio | 0.32 | 0.32 |

| Modulus of elasticity | 179 GPa | 26000 ksi |

Chemical Compatibility and Incompatibility of Werkstoff NR.2.4360 Heavy Hex Nut

| Chemical Compatibility | Chemical Incompatibility |

|---|---|

| Sea Water - Excellent | Nitric Acid (HNO3) - Poor |

| Acetic Acid - Excellent | Chlorine (Cl2) gas - Poor |

| Citric Acid - Excellent | Hydrochloric Acid (HCl) - Variable |

Surface Coating of UNS 4400 Wing Nuts

| Mirror Buffed | Epoxy Coating | Hot Dipped Galvanizing | Passivation | Electro Polished |

| Teflon Coating | Zinc Plating | Oxidized | Chrome Plating |

| STANDARD | WERKSTOFF NR.(Germany) | UNS(North America) | JIS (Japan) | BS (British Standard) | GOST (Russia) | AFNOR (France) | EN (Europe) |

| Monel 400 | 2.4360 | N04400 | NW 4400 | NA 13 | МНЖМц 28-2,5-1,5 | NU-30M | NiCu30Fe |

Chemical Composition of EN 2.4360 Lock Nut

Carbon

Manganese

Silicon

Sulphur

Copper

Iron

Nickel

Mechanical Properties of Nickel Alloy 400 Panel Nuts

8.44 g/cm³

1350 °C (2460 °F)

up to 480 C

8.8 g/cm³

1350 °C (2460 °F)

up to 1000° F

Psi – 80,000 , MPa – 550

Psi – 35,000 , MPa – 240

40 %

Get in Touch

Call us on

Email us