Alloy C-2000 Coupling Nuts Length

- 3 mm to 200 mm

The Hastelloy C2000 Nuts are made of molybdenum, chromium, and nickel. These high-quality Nuts share a long history of efficient and effective working in chemical processing industries. The vital constituents of these nuts offer excellent resistance in all acidic environments, especially in hydrofluoric, sulphuric, and hydrochloric. These high-grade nuts are suitable for all temperature ranges and perfect for many complex industrial applications. The Hastelloy C-2000 Nuts have workability that remains unaffected in not only acidic environments but also in the harsh atmosphere of chlorides and halides. These Hastelloy Alloy C-2000 Nuts have workability that remains unaltered in the assault in stress consumption opening. These ASME SB574 UNS N06200 Hex Nut are available in a wide range.

Table of Content

Dalloyed Works is a prominent manufacturer, supplier, and distributor of these high-quality products, Alloy C-2000 Lock Nuts, worldwide. Also, we are best known for making customized shapes, sizes, dimensions, and structures. We test these nuts under the strict supervision of our experts and quality analysts. We are packing these well-tested Nuts in suitable materials to offer safe delivery at the client's locations. We are providing these Nickel Alloy C-2000 Nuts in the required amount and within the decided time.

Hastelloy C2000 Nuts Specification

Alloy C-2000 Coupling Nuts Length

Nickel Alloy C-2000 Eye Nuts Specification

WERKSTOFF NR. 2.4675 Dome Nuts Sizes

UNS N06200 Nylock Nuts Standard

ASTM B574 Panel Nuts Threads

Hastelloy C2000 Nuts Markings

DIN 2.4675 Square Nuts Head Drive

ASME SB574 Hex Nuts Applications

C-2000 Hastelloy Lock Nuts Form

Hastelloy® Alloy C-2000 Heavy Hex Nuts Manufacturing Method

Alloy UNS N06200 Flange Lock Nut Packaging

2.4675 Hastelloy Hex Nut Origin

Nickel C2000 Eye Nuts Inspection Methods

ASTM B574 Hastelloy® Alloy C2000 Dome Nut Test Certificates

Types of Hastelloy C-2000 Nuts

Hastelloy® Alloy C-2000 Dome Nuts

UNS N06200 Coupling Nuts

Alloy C2000 Flange Nuts

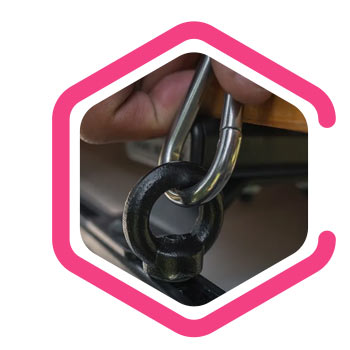

2.4675 Eye Nut

Nickel Alloy C-2000 Heavy Hex Nuts

C-2000 Hastelloy Hex Nuts

Hastelloy Alloy C2000 Lock Nut

Alloy C-2000 Panel Nut

Nickel C2000 Square Nuts

| Nut Size (mm) | Diameter* (mm) | Height (mm) | ||

|---|---|---|---|---|

| Hex Nut | Jam Nut | Nylock Nut | ||

| 3mm | 5.5 | 2.4 | 1.8 | 4 |

| 2mm | 4 | 1.6 | 1.2 | – |

| 12mm | 19 | 10 | 6 | 12 |

| 5mm | 8 | 4 | 2.7 | 5 |

| 2.5mm | 5 | 2 | 1.6 | – |

| 7mm | 11 | 5.5 | 3.5 | – |

| 4mm | 7 | 3.2 | 2.2 | 5 |

| 14mm | 22 | 11 | 7 | 14 |

| 6mm | 10 | 5 | 3.2 | 6 |

| 16mm | 24 | 13 | 8 | 16 |

| 8mm | 13 | 6.5 | 4 | 8 |

| 18mm | 27 | 15 | 9 | 18.5 |

| 10mm | 17 | 8 | 5 | 10 |

| 20mm | 30 | 16 | 10 | 20 |

Dimension of ASTM B574 UNS N06200 Square Nuts

| Nominal Size or Basic Major Thread Diameter | F | G | H | ||||||

| Width Across Flats |

Width Across Corners |

Thickness | |||||||

| Basic | Max | Min | Max | Min | Basic | Max | Min | ||

| 1/2 | .5000 | 3/4 | .750 | .736 | .866 | .840 | 7/16 | .448 | .427 |

| 1/4 | .2500 | 7/16 | .438 | .428 | .505 | .488 | 7/32 | .226 | .212 |

| 2-1/2 | 2.5000 | 3-3/4 | 3.750 | 3.625 | 4.330 | 4.133 | 2-5/32 | 2.209 | 2.105 |

| 5/16 | .3125 | 1/2 | .500 | .489 | .577 | .557 | 17/64 | .273 | .258 |

| 2-1/4 | 2.2500 | 3-3/8 | 3.375 | 3.263 | 3.897 | 3.719 | 1-15/16 | 1.986 | 1.890 |

| 3/8 | .3750 | 9/16 | .562 | .551 | .650 | .628 | 21/64 | .337 | .479 |

| 1-3/8 | 1.3750 | 2-1/16 | 2.062 | 1.994 | 2.382 | 2.273 | 1-11/64 | 1.206 | 1.138 |

| 2 | 2.0000 | 3 | 3.000 | 2.900 | 3.464 | 3.306 | 1-23/32 | 1.763 | 1.675 |

| 7/16 | .4375 | 11/16 | .688 | .675 | .794 | .768 | 3/8 | .385 | .365 |

| 1/2 | .5000 | 3/4 | .750 | .736 | .866 | .840 | 7/16 | .448 | .427 |

| 9/16 | .5625 | 7/8 | .875 | .861 | 1.010 | .982 | 31/64 | .496 | .473 |

| 2-3/4 | 2.7500 | 4-1/8 | 4.125 | 3.988 | 4.763 | 4.546 | 2-3/8 | 2.431 | 2.319 |

| 5/8 | .6250 | 15/16 | .938 | .922 | 1.083 | 1.051 | 35/64 | .559 | .535 |

| 1-5/8 | 1.6250 | 2-7/16 | 2.438 | 2.356 | 2.815 | 2.686 | 1-25/64 | 1.429 | 1.353 |

| 3/4 | .7500 | 1-1/8 | 1.125 | 1.088 | 1.299 | 1.240 | 41/64 | .665 | .617 |

| 1-3/4 | 1.7500 | 2-5/8 | 2.625 | 2.538 | 3.031 | 2.893 | 1-1/2 | 1.540 | 1.460 |

| 1 | 1.0000 | 1-1/2 | 1.500 | 1.450 | 1.732 | 1.653 | 55/64 | .887 | .831 |

| 1-1/8 | 1.1250 | 1-11/16 | 1.688 | 1.631 | 1.949 | 1.859 | 31/32 | .999 | .939 |

| 7/8 | .8750 | 1-5/16 | 1.312 | 1.269 | 1.516 | 1.447 | 3/4 | .776 | .724 |

| 1-1/2 | 1.500 | 2-1/4 | 2.250 | 2.175 | 2.598 | 2.480 | 1-9/32 | 1.ASTM A194 GR. 8 | 1.245 |

Heat Treatment of Hastelloy C2000 Nuts

| Condition as supplied by AWI | Type | Temperature | Cooling | Time |

|---|---|---|---|---|

| Annealed or Spring Temper | Stress Relieve | 400 – 450 °C (750 – 840 °F) | Air | 2 Hr |

Annealed Temperature of Nickel Alloy C2000 Hex Nut

| Annealed | ||

|---|---|---|

| Approx. tensile strength | 1300 – 1600 N/mm² | 189 – 232 ksi |

| Approx. operating temperature depending on load** and environment | -200 to +400 °C | -330 to +750 °F |

| Approx. tensile strength | <1000 N/mm² | <145 ksi |

| Approx. operating temperature depending on load** and environment | -200 to +400 °C | -330 to +750 °F |

Physical Properties of ASTM B574 Panel Nuts

| Physical | Properties |

| Elastic Modulus(Gpa) | 218 |

| Thermal Conductivity | 9.1 |

| Electrical Resistivity | 128 |

| Specific Heat | 428 |

Characteristics of Hastelloy 2.4675 Flange Nuts

Equivalent Grades of Hastelloy® Alloy C2000 Lock Nuts

| STANDARD | WERKSTOFF NR.(Germany) | UNS(North America) |

| Hastelloy C2000 | 2.4675 | N06200 |

Chemical Composition of Hastelloy C2000 Nuts

Silicon

Carbon

Sulphur

Manganese

Copper

Iron

Aluminium

Chromium

Cobalt

Molybdenum

Phosphorus

Mechanical Properties of UNS N06200 Heavy Hex Nuts

310 MPa

690 MPa

45%

1399 °C

8.5 g/cm³

400 – 450 °C

Get in Touch

Call us on

Email us