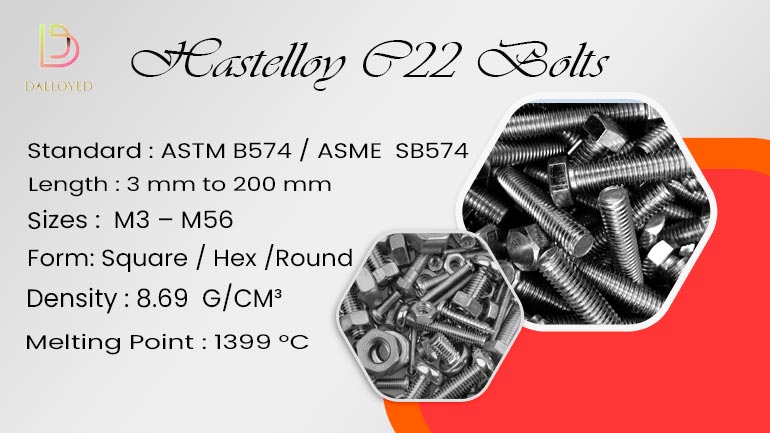

Hastelloy C-22 Bolts Specification

- ASME SB574

- ASTM B574

Hastelloy C22 Bolts have become a versatile product with the combination of alloying elements like molybdenum, tungsten, nickel, and chromium. This offers well-enhanced pitting, stress corrosion cracking, and crevice corrosion cracking resistance. As these bolts contain an outstanding amount of chromium content, they provide excellent resistance to oxidizing media. The presence of tungsten and molybdenum alloy makes these bolts provide superior resistance to reducing media. Also, these B574 UNS N06022 Heavy Hex Bolt offer extended functional life services in inorganic and organic compounds-containing situations. These high qualities of bolts are too provide excellent resistance to the environment. The high-quality fabricated bolts are all according to national and international standards. These bolts are available in various ranges of designations, shapes, specifications, and custom-made specifications according to demand. These high-graded Hastelloy Alloy C22 Bolts are fabricated using advanced technology and modern tools.

Table of Content

Dalloyed Works is the prominent manufacturer, supplier, and exporter of supreme quality Alloy Hastelloy C22 globally with the product's high qualities and excellent services. At our high-tech manufacturing unit, the development of these Nickel C22 Bolts is done under the proper guidance of our professional experts. In the end, We Dalloyed Works conducted several destructive and non-destructive tests on the finished product under the supervision of quality experts.

Hastelloy C22 Bolts Specification

Hastelloy C-22 Bolts Specification

Alloy C22 Hex Bolt Length

ASME SB574 Heavy Hex Bolt Sizes

Hastelloy® Alloy C22 U Bolts Standard

C22 Hastelloy J Bolts Threads

ASME SB574 Hastelloy C22 Square Bolts Surface Coating

WERKSTOFF NR. 2.4602 Anchor Bolts Head Drive

UNS N06022 Eye Bolts Manufacturing Process

NW 6022 Allen Bolts Form

EN 2.4602 Countersunk Bolts Benefits

Hastelloy C22 Bolts Packaging

ASTM B574 Stud Bolts Origin

Nickel Alloy C22 Threaded Bolts Inspection Methods

Haynes Alloy C22 T Bolts Test Certificates

Most Common Types of C22 Nickel Alloy Bolts

Hastelloy 2.4602 U Bolts

Hastelloy Alloy C22 Threaded Bolt

ASTM B574 UNS N06022 Anchor Bolt

DIN 2.4602 Stud Bolt

Alloy C22 Elevator Bolt

2.4602 Hastelloy C22 J Bolts

ASTM B574 Heavy hex Head Bolts

Nickel C22 Hex Bolts

UNS 6022 Eye Bolts

Chemical Compatibility and Incompatibility of Hastelloy C22 Bolts

| Chemical Compatibility | Chemical Incompatibility |

|---|---|

| Sulfuric Acid - Good | Molten iron - Poor |

| Nitric Acid - Excellent | Aluminum - Poor |

| sodium hydroxide- Good | Hydrofluoric acid - Poor |

| Phosphoric Acid - Excellent | Chlorine - Poor |

| Length | Diameter |

|---|---|

| 8” | |

| 7” – 7 1/2" | 1 1/4" |

| 5” – 5 1/2" | 1 1/8” |

| 5” – 5 1/2" | 1” |

| 4” – 4 1/2” | 7/8” |

| 3” – 3 3/4" | 3/4" |

| 2” – 2 3/4" | 5/8” |

| 1 1/2" – 1 3/4" | 1/2" |

Dimensions of ASME SB574 Structural Bolts

| Nominal Size or Basic Product Diameter |

Full-Size Body Diameter, E |

Width Across Flats, F |

Width Across Corners, G |

Head Height, H Basic | Radius of Fillet, R |

Nominal Thread Length for Bolt Lengths, LT |

|||||||||

| inch | mm | Min | Max | Basic inch |

Min | Max | Min | Max | Basic inch |

Min | Max | Min | Max | 6 in. and Shoter |

Over 6 in. |

| 4 | 4 | 3.975 | 4.111 | 6 | 5.8 | 6 | 6.612 | 6.928 | 2 11⁄16 | 2.424 | 2.764 | 0.06 | 0.19 | 8.25 | 8.5 |

| 1⁄4 | 0.25 | 0.237 | 0.26 | 7⁄16 | 0.425 | 0.438 | 0.484 | 0.505 | 11⁄64 | 0.15 | 0.188 | 0.01 | 0.03 | 0.75 | 1 |

| 3⁄4 | 0.75 | 0.729 | 0.768 | 11⁄8 | 1.088 | 1.125 | 1.24 | 1.299 | 1⁄2 | 0.455 | 0.524 | 0.02 | 0.06 | 1.75 | 2 |

| 1 1⁄4 | 1.25 | 1.223 | 1.277 | 1 7⁄8 | 1.812 | 1.875 | 2.066 | 2.165 | 27⁄32 | 0.749 | 0.876 | 0.03 | 0.09 | 2.75 | 3 |

| 1 3⁄4 | 1.75 | 1.716 | 1.785 | 2 5⁄8 | 2.538 | 2.625 | 2.893 | 3.031 | 1 5⁄32 | 1.054 | 1.196 | 0.04 | 0.12 | 3.75 | 4 |

| 2 1⁄4 | 2.25 | 2.214 | 2.305 | 3 3⁄8 | 3.262 | 3.375 | 3.719 | 3.897 | 1 1⁄2 | 1.327 | 1.548 | 0.06 | 0.19 | 4.75 | 5 |

| 2 3⁄4 | 2.75 | 2.711 | 2.827 | 4 1⁄8 | 3.988 | 4.125 | 4.546 | 4.763 | 1 13⁄16 | 1.632 | 1.869 | 0.06 | 0.19 | 5.75 | 6 |

| 3 3⁄4 | 3.75 | 3.726 | 3.858 | 5 5⁄8 | 5.437 | 5.625 | 6.198 | 6.495 | 2 1⁄2 | 2.241 | 2.572 | 0.06 | 0.19 | 7.75 | 8 |

| 3 1⁄4 | 3.25 | 3.21 | 3.335 | 4 7⁄8 | 4.712 | 4.875 | 5.372 | 5.629 | 2 3⁄16 | 1.936 | 2.251 | 0.06 | 0.19 | 6.75 | 7 |

| 5⁄16 | 0.3125 | 0.298 | 0.324 | 1⁄2 | 0.484 | 0.5 | 0.552 | 0.577 | 7⁄32 | 0.195 | 0.235 | 0.01 | 0.03 | 0.875 | 1.125 |

| 7⁄16 | 0.4375 | 0.421 | 0.452 | 5⁄8 | 0.603 | 0.625 | 0.687 | 0.722 | 19⁄64 | 0.272 | 0.316 | 0.01 | 0.03 | 1.125 | 1.375 |

| 3⁄8 | 0.375 | 0.36 | 0.388 | 9⁄16 | 0.544 | 0.562 | 0.62 | 0.65 | 1⁄4 | 0.226 | 0.268 | 0.01 | 0.03 | 1 | 1.25 |

| 5⁄8 | 0.625 | 0.605 | 0.642 | 15⁄16 | 0.906 | 0.938 | 1.033 | 1.083 | 27⁄64 | 0.378 | 0.444 | 0.02 | 0.06 | 1.5 | 1.75 |

| 1 1⁄8 | 1.125 | 1.098 | 1.149 | 1 11⁄16 | 1.631 | 1.688 | 1.859 | 1.949 | 3⁄4 | 0.658 | 0.78 | 0.03 | 0.09 | 2.5 | 2.75 |

| 7⁄8 | 0.875 | 0.852 | 0.895 | 1 5⁄16 | 1.269 | 1.312 | 1.447 | 1.516 | 37⁄64 | 0.531 | 0.604 | 0.02 | 0.06 | 2 | 2.25 |

| 1 3⁄8 | 1.375 | 1.345 | 1.404 | 2 1⁄16 | 1.994 | 2.062 | 2.273 | 2.382 | 29⁄32 | 0.81 | 0.94 | 0.03 | 0.09 | 3 | 3.25 |

| 1 5⁄8 | 1.625 | 1.591 | 1.658 | 2 7⁄16 | 2.356 | 2.438 | 2.616 | 2.815 | 1 3⁄32 | 0.978 | 1.116 | 0.03 | 0.09 | 3.5 | 3.75 |

| 1 7⁄8 | 1.875 | 1.839 | 1.912 | 2 13⁄16 | 2.719 | 2.812 | 3.099 | 3.248 | 1 1⁄4 | 1.13 | 1.276 | 0.04 | 0.12 | 4 | 4.25 |

| 3 | 3 | 2.961 | 3.081 | 4 1⁄2 | 4.35 | 4.5 | 4.959 | 5.196 | 2 | 1.815 | 2.06 | 0.06 | 0.19 | 6.25 | 6.5 |

| 3 1⁄2 | 3.5 | 3.461 | 3.589 | 5 1⁄4 | 5.075 | 5.25 | 5.786 | 6.062 | 2 5⁄16 | 2.057 | 2.38 | 0.06 | 0.19 | 7.25 | 7.5 |

| 2 | 2 | 1.964 | 2.039 | 3 | 2.9 | 3 | 3.306 | 3.464 | 1 11⁄32 | 1.175 | 1.388 | 0.04 | 0.12 | 4.25 | 4.5 |

| 1 1⁄2 | 1.5 | 1.47 | 1.531 | 2 1⁄4 | 2.175 | 2.25 | 2.48 | 2.598 | 1 | 0.902 | 1.036 | 0.03 | 0.09 | 3.25 | 3.5 |

| 1⁄2 | 0.5 | 0.482 | 0.515 | 3⁄4 | 0.725 | 0.75 | 0.826 | 0.866 | 11⁄32 | 0.302 | 0.364 | 0.01 | 0.03 | 1.25 | 1.5 |

| 2 1⁄2 | 2.5 | 2.461 | 2.559 | 3 3⁄4 | 3.625 | 3.75 | 4.133 | 4.33 | 1 21⁄32 | 1.479 | 1.708 | 0.06 | 0.19 | 5.25 | 5.5 |

| 1 | 1 | 0.976 | 1.022 | 1 1⁄2 | 1.45 | 1.5 | 1.653 | 1.732 | 43⁄64 | 0.591 | 0.7 | 0.03 | 0.09 | 2.25 | 2.5 |

Weight Chart of Werkstoff NR. 2.4602 Anchor Bolt

| APPROX. WEIGHT IN KGS FOR 100 NOS | ||||||||||

| LENGTH in mm | DIAMETER (METRIC) | |||||||||

| M5 | M6 | M12 | M8 | M10 | M16 | M14 | M20 | M18 | M22 | |

| 25 | 0.660 | 0.897 | 5.252 | 1.871 | 3.660 | 8.170 | ||||

| 35 | 0.804 | 1.120 | 5.974 | 2.271 | 4.223 | 11.416 | 10.000 | 19.608 | 16.026 | |

| 45 | 0.958 | 1.340 | 6.859 | 2.671 | 4.840 | 12.821 | 10.504 | 21.739 | 17.241 | |

| 55 | 1.560 | 7.740 | 3.071 | 5.464 | 14.409 | 11.628 | 23.810 | 18.868 | 30.120 | |

| 65 | 1.781 | 8.621 | 3.472 | 6.083 | 16.026 | 12.626 | 26.455 | 21.008 | 34.014 | |

| 75 | 2.000 | 9.506 | 3.873 | 6.702 | 17.606 | 13.228 | 29.070 | 23.256 | 39.063 | |

| 75 | 2.000 | 9.506 | 3.873 | 6.702 | 17.606 | 13.228 | 29.070 | 23.256 | 39.063 | |

| 150 | 16.340 | 11.312 | 29.412 | 22.222 | 48.544 | 37.594 | 58.824 | |||

| 16 | 0.448 | 0.743 | 1.590 | 3.211 | ||||||

| 160 | 17.241 | 11.905 | 31.056 | 24.272 | 50.505 | 40.984 | 61.728 | |||

| 60 | 1.670 | 8.183 | 3.270 | 5.774 | 15.244 | 12.255 | 25.126 | 20.000 | 32.051 | |

| 30 | 0.737 | 1.010 | 5.574 | 2.070 | 3.912 | 10.707 | 9.690 | 18.657 | ||

| 380 | 37.037 | 66.667 | 108.696 | |||||||

| 360 | 35.211 | 63.291 | 104.167 | |||||||

| 340 | 33.557 | 60.241 | 98.039 | |||||||

| 320 | 31.646 | 56.818 | 92.593 | |||||||

| 300 | 29.940 | 20.325 | 53.763 | 87.719 | 104.167 | |||||

| 40 | 0.881 | 1.230 | 6.410 | 2.470 | 4.533 | 12.107 | 10.288 | 20.747 | 16.667 | |

| 400 | 39.063 | 69.444 | 113.636 | |||||||

| 240 | 24.510 | 16.722 | 43.860 | 71.429 | 84.746 | |||||

| 180 | 19.011 | 13.123 | 34.247 | 26.882 | 55.556 | 67.568 | ||||

| 280 | 28.090 | 19.157 | 50.505 | 81.967 | 98.039 | |||||

| 220 | 22.624 | 15.528 | 40.650 | 65.789 | 79.365 | |||||

| 260 | 26.316 | 17.921 | 47.170 | 76.923 | 90.909 | |||||

| 200 | 20.833 | 14.327 | 37.594 | 29.586 | 60.976 | 49.020 | 73.529 | |||

| 50 | 1.030 | 1.450 | 7.299 | 2.870 | 5.155 | 13.624 | 11.261 | 22.727 | 17.857 | 28.409 |

| 120 | 13.624 | 9.506 | 24.631 | 18.797 | 40.984 | 32.895 | 50.000 | |||

| 250 | 25.381 | 17.301 | 45.455 | 74.627 | 87.719 | |||||

| 130 | 14.535 | 10.101 | 26.316 | 20.000 | 43.478 | 34.722 | 52.632 | |||

| 70 | 1.890 | 9.058 | 3.671 | 6.394 | 16.835 | 12.987 | 27.778 | 22.124 | 35.461 | |

| 170 | 18.116 | 12.500 | 32.680 | 53.191 | 64.935 | |||||

| 80 | 2.111 | 10.000 | 4.072 | 7.013 | 18.248 | 13.889 | 30.303 | 24.510 | 40.000 | |

| 190 | 19.920 | 13.736 | 35.971 | 58.140 | 70.423 | |||||

| 90 | 10.917 | 4.472 | 7.634 | 19.841 | 14.925 | 33.113 | 26.042 | 41.667 | ||

| 100 | 11.820 | 4.873 | 8.251 | 21.459 | 16.340 | 35.714 | 27.778 | 46.296 | ||

| 110 | 12.723 | 8.881 | 23.041 | 17.730 | 38.168 | 31.250 | 47.170 | |||

| 140 | 15.432 | 10.707 | 27.933 | 20.833 | 46.296 | 35.461 | 55.556 | |||

Hastelloy C22 Bolts Equivalent

| STANDARD | WERKSTOFF NR.(Germany) | UNS(North America) | JIS(Japan) | GOST(Russia) | EN(Europe) | OR |

| Hastelloy C22 | 2.4602 | N06022 | NW 6022 | - | NiCr21Mo14W | - |

Chemical Composition of UNS 6022 Countersunk Bolts

Carbon

Manganese

Silicon

Sulphur

Iron

Nickel

Chromium

Cobalt

Molybdenum

Phosphorus

Mechanical Properties of Haynes Alloy C22 Threaded Bolts

Psi – 1,00,000 , MPa – 690

Psi – 45000 , MPa – 310

45 %

8.69 g/cm3

1399 °C (2550 °F)

56%

Physical Properties of ASTM B574 UNS N06022 Square Bolt

| Mean Coeff Thermal Expansion | 6.9 |

|---|---|

| Specific Gravity | 8.69 lb/in3 |

| Specific Heat Btu/lb/Deg F - [32-212 Deg F] | 0.1 |

| Modulus of Elasticity Tension | 29.9 |

| Thermal Conductivity | 70 |

Applications of DIN 2.4602 Heavy Hex Head Bolt

Get in Touch

Call us on

Email us